From August 15-31, 2024, our team completed another successful annual maintenance at AT Biopower in Pichit. With its 100% Rice-Husk boiler using suspension-fired combustion technology from Wellons USA,efficiency is key. Thanks to our long-standing partnership with Wellons, we provide exceptional repairs and engineering support.

Continuous Efficiency:

Through “TEKE cleaning” AGON Pacific improved the boiler’s performance, ensuring no downtime throughout 2023.

AT Biopower integrates seamlessly with the local community, showing how power plants can be both efficient and eco-friendly.

We’re thrilled to announce the arrival of Boiler Superheater Coil, crafted specifically for your heating system needs.

This essential component has just been delivered and ready for boiler maintenance and upgrade projects.

Ensure your equipment operates efficiently and smoothly with this high-quality, custom-made part.

Contact us today to learn more or to place your order!

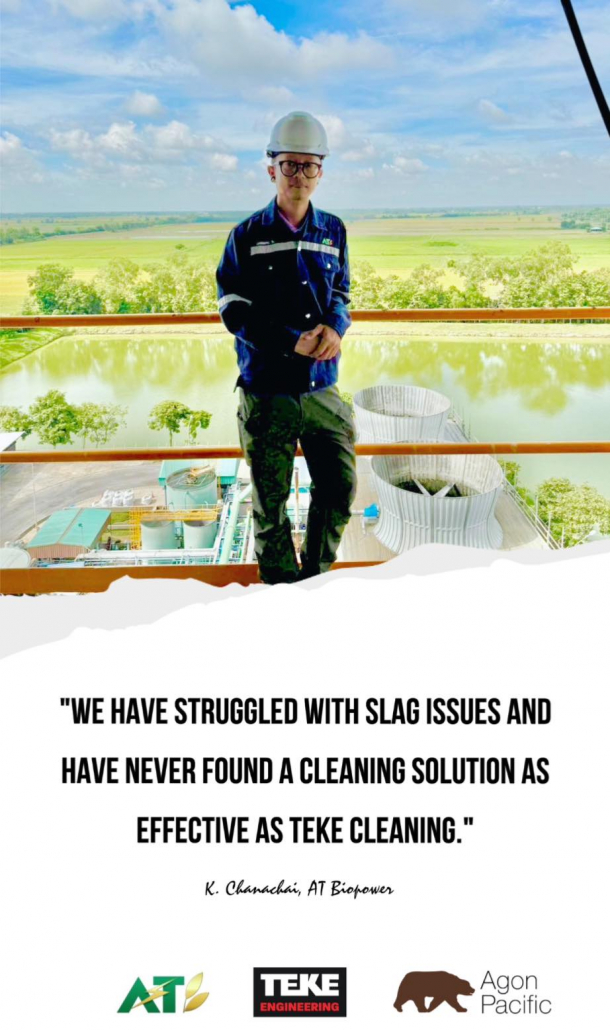

“We were thoroughly impressed with the TEKE Boiler Cleaning service provided during our 2023 outage.

Since early this year, we have struggled with slag issues in our boiler and have never found a cleaning solution as effective as TEKE Cleaning.

The service significantly improved our boiler’s efficiency.

We are grateful to the AGON Pacific team for bringing this technology to us, enabling our operations to run at full efficiency.”

Thank you to our valued customer for sharing their experience!

We’re proud to see our TEKE Boiler Cleaning service making such a positive impact.

Blog Posts

The 20 latest Blog Posts

- Revolutionizing Forestry: SCG Adopts Kesla 18RH-II for Smarter, Faster Harvesting!

- Project Success Story: Recovery Boiler Floor Tube Replacement

- Project Completed: Boiler Stack Replacement

- Successful Boiler Maintenance at AT Biopower!

- Just Delivered: Boiler Superheater Coil!

- Customer Success Spotlight: Boiler Cleaning by AGON Pacific

- Check out our project: A Boiler Panel with Overlay Welding Fabrication!

- EXCITING NEWS!

- Economizer and Superheater Module Successfully Shipped to America

- WELCOME THE ISGEC TEAM TO OUR OFFICE TODAY!

- DOES FUEL CHANGES OR FUEL MISMATCHES WITH THE DESIGN INTERRUPT YOU?

- AGON PACIFIC NOW OFFERS TURBINE CLEANING SERVICES

- REPLACING THE FLOOR TUBE PANELS

- PARTICIPATING IN THE MEETING AT THE NATIONAL ASSEMBLY OF THAILAND ABOUT WASTE MANAGEMENT AND ENVIRONMENTAL SUSTAINABILITY

- We Have Received The Green Industry Level 3 Certificate !

- Exciting News Alert!

- We’re Thrilled to Announce That Agon Pacific Has Achieved ISO 9001:2015 and ISO 14001:2015 Certifications!

- WE’RE PROUD TO ANNOUNCE THAT WE’VE ACHIEVED AN ‘A’ RANK BY INSEE GROUP

- RELOCATION HEADQUARTER OFFICE

- Thank you GPSC for awarding us a certificate of excellence vendor. it is a great honor. We will keep improving our service.

Pages

Available Pages

- About Us

- Agon Pacific In Brief

- Boiler Inspection

- Boiler Maintenance

- Boiler Pressure Parts Manufacturing

- Boiler Upgrade and Modification

- capabilities

- Certification

- Contact Us

- CSR Activities

- Home

- Job Dashboard

- Jobs

- Mission and Vision

- News

- Our Business

- Our Services

- Projects

- Quality Policy

- Spare Parts and Material Supply

- Submit Job Form

- Technical Consulting and Engineering Service

Categories

Archives by Subject:

Monthly

Archives by Month:

- February 2025

- December 2024

- September 2024

- August 2024

- July 2024

- May 2024

- April 2024

- March 2024

- December 2023

- October 2023

- August 2023

- July 2023

- May 2023

- March 2023

- December 2022

- April 2021

- November 2020

- April 2020

- February 2020

- January 2020

- December 2019

- May 2019

- February 2019

- January 2019

- December 2018

- October 2018

- September 2018

- December 2017

- November 2017

- October 2017

- September 2017

- August 2017

- June 2017

- January 2017